- Home

- Products

- Automotive Connector

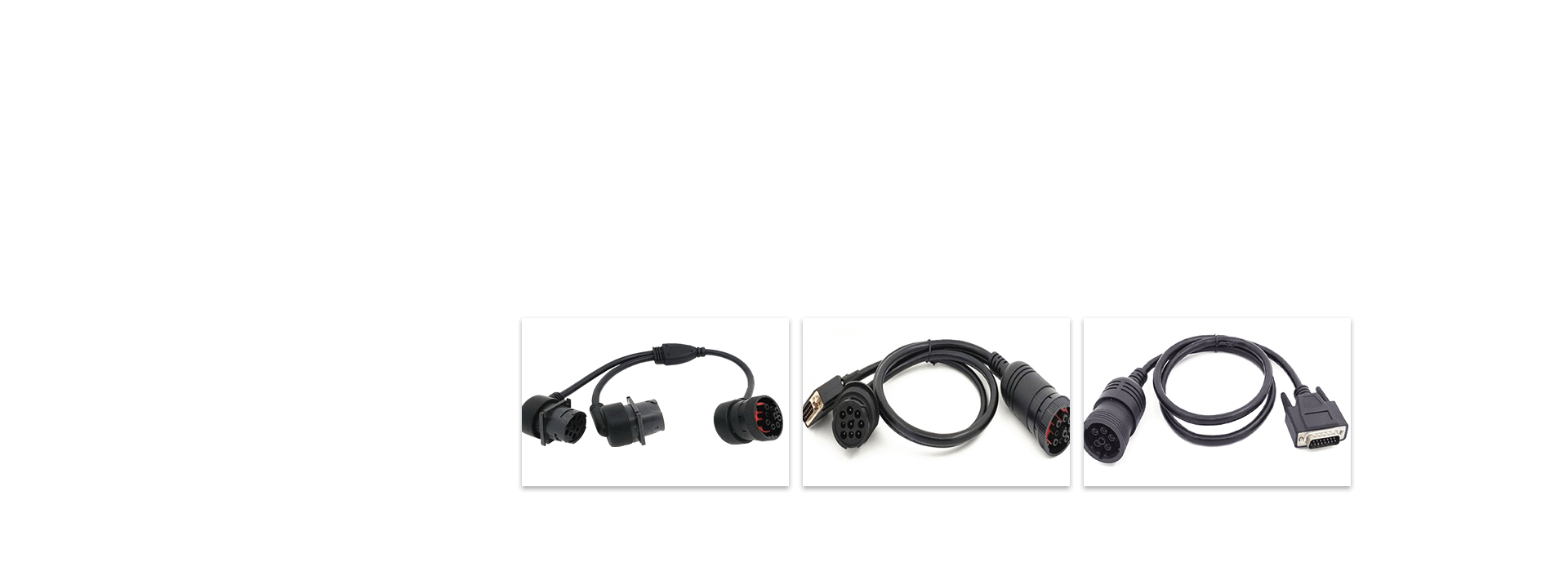

- Automotive Diagnostic Cable

- other

- plastic parts

- Dechi diagnose Cable

- Electronic products

- New energy charging CABLE

- OBD GPS Tracking Cables

- OBD II Vehicle Diagnostic Cables

- OBD2 Splitter Y Cables

- OBDII Detection Cable

- OBDII Extension Cable

- PCBA

- Plastic molding class

- SMT

- Urea Pump Detection Line

- Waterproof Cable

- About Us

- Quality

- News

- Contact Us

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search